|

Gongyi Aluminum Co.,Ltd.

|

5052 Aluminum Strip-Gongyi Shengzhou Metal

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

5052 aluminum strip, the main alloying element of 5052 is magnesium

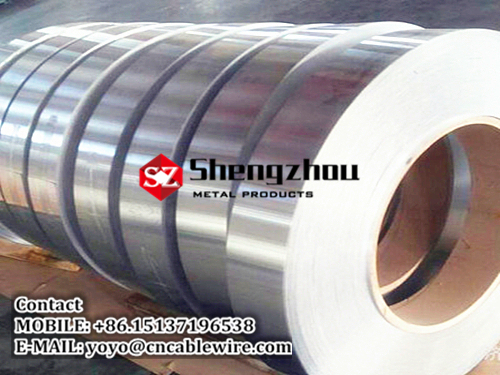

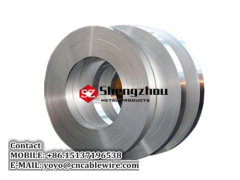

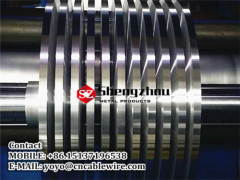

5052 Aluminum Strip

5052 aluminum strip, the main alloying element of 5052 is magnesium, which has good forming processability, corrosion resistance, weldability and medium strength,it is used to manufacture aircraft fuel tanks, oil pipes, and transportation vehicles, ship sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, etc.

Characteristic of 5052 Aluminum Strip

It is Al-Mg series rust-proof aluminum. Compared with 3A21, the strength of 5A02 is higher, especially the fatigue strength is higher. Similar to 3A21, it has high plasticity and corrosion resistance; heat treatment cannot be strengthened, weldability by contact welding and hydrogen atom welding is good, and there is a tendency of crystal cracking during argon arc welding. The alloy has good machinability under cold hardening and semi-cold hardening, and poor machinability under annealing condition,and it can be polished.

Mechanical Properties of 5052 Aluminum Strip

Tensile strength σb (MPa): ≤225;

Elongation δ5 (%): ≥10;

Note: Longitudinal mechanical properties of bars at room temperature;

Specimen size: bar diameter (square bar, hexagonal bar inscribed circle diameter) ≤ 150.

Heat Treatment Specification of 5052 Aluminum Strip

1.Homogenization annealing: heating 440 ℃, heat preservation 12 ~ 14 h, air cooling.

2.Rapid annealing: heating 350 ~ 410 ℃; holding time 30 ~ 120min; air or water cooling.

3.High temperature annealing: heating 350 ~ 420 ℃; finished product thickness ≥ 6mm or<6mm, holding time is 2 ~ 10min or 10 ~ 30min; air cooling.

4.Low temperature annealing: heating 250 ~ 300 ℃ or 150 ~ 180 ℃; holding time is 1 ~ 2h, air cooling.

Introduction of our company

Gongyi Shengzhou Metal Products Co.,Ltd. is a professional Aluminium Strip Suppliers and Aluminum Circles manufacturers,mainly supply Aluminum Circles, Aluminium discs, Aluminum Strip, Food Box Material Aluminum Foil, Aluminum Circles for Kitchenware etc. series of aluminum products, sincerely welcome everyone to visit.